Metallic Gaskets

Metallic gaskets are engineered sealing solutions designed for high-pressure, high- temperature, and critical service applications where reliability and leak-tight performance are non-negotiable. They are widely used in process industries where flange integrity, thermal cycling, pressure fluctuations, and aggressive media demand robust sealing systems.

We manufacture and supply a comprehensive range of metallic gaskets conforming to international standards such as ASME, API, and relevant customer specifications. Our gaskets are engineered to suit a wide variety of flange types, pressure classes, and operating conditions, ensuring consistent performance across demanding industrial environments.

With a strong focus on material selection, sealing philosophy, and dimensional accuracy, our metallic gaskets are supplied for both standard and critical applications across onshore and offshore installations.

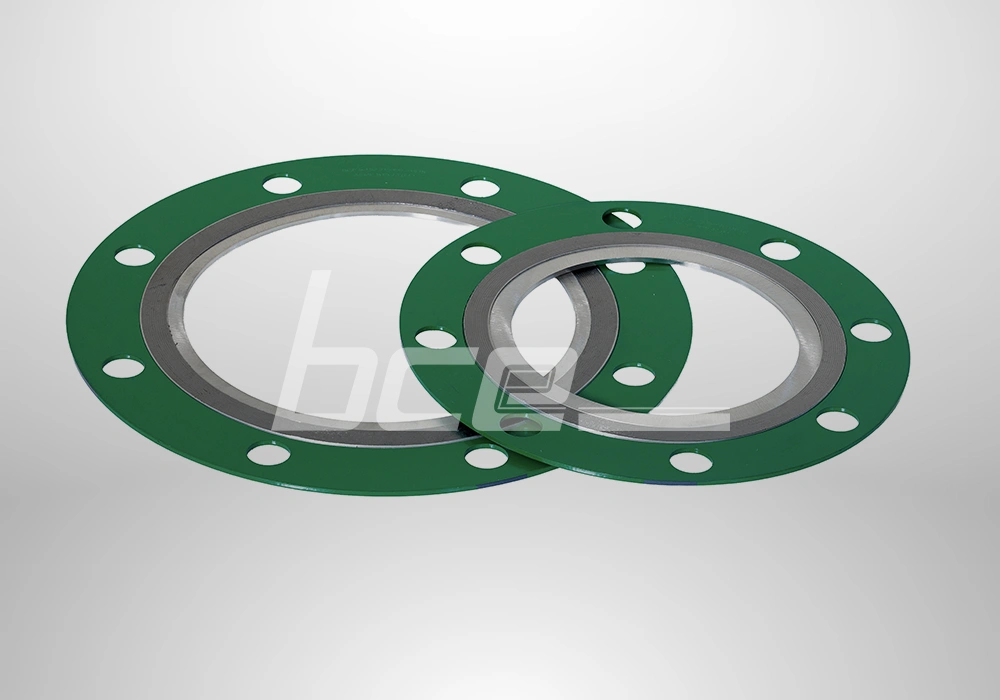

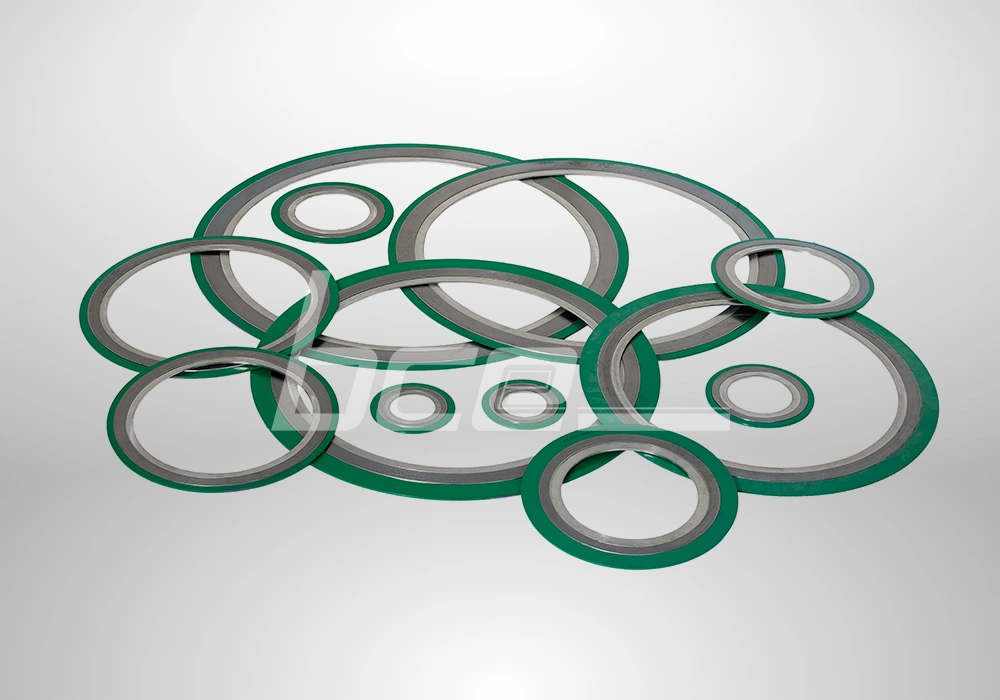

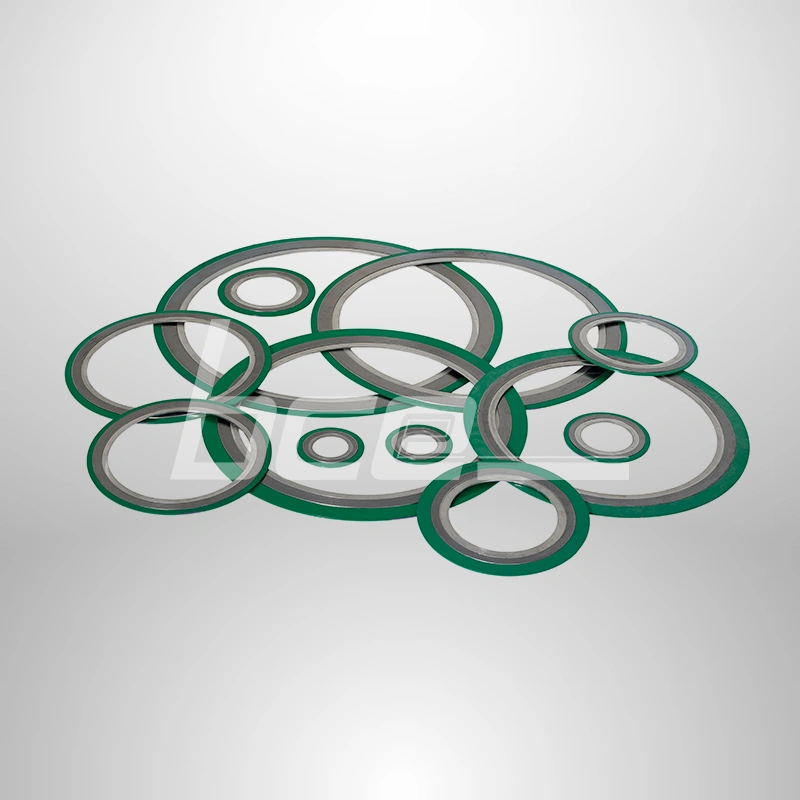

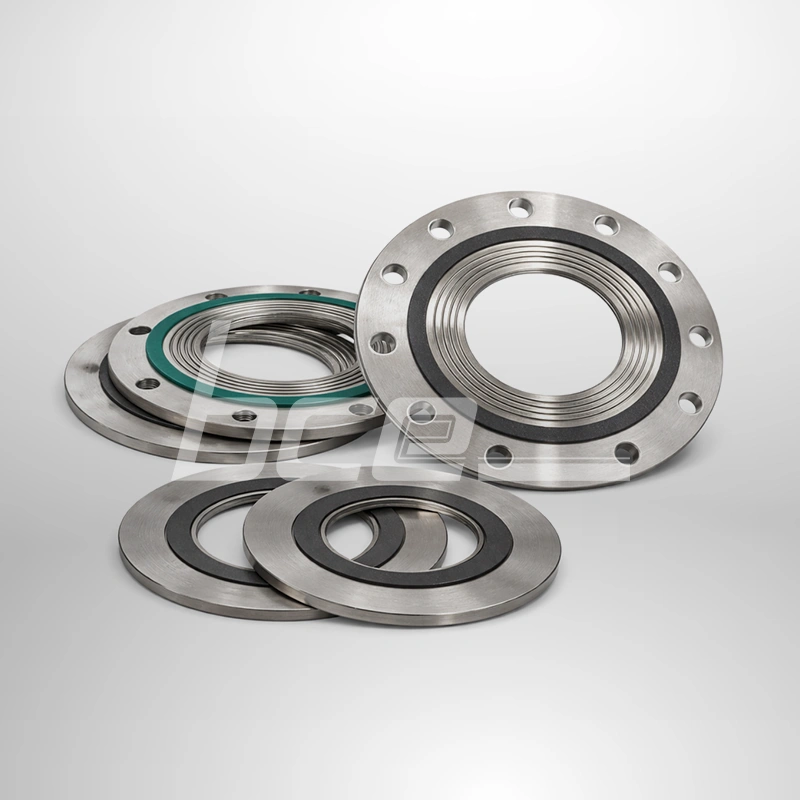

Spiral Wound Gaskets (SPWG)

Spiral Wound Gaskets are among the most versatile and widely used metallic gaskets for piping and equipment flanges. They are designed to provide excellent sealing performance under varying pressures and temperatures, making them suitable for a broad range of services including steam, hydrocarbons, chemicals, and utilities.

Their unique construction allows them to combine the strength of metal with the sealing efficiency of soft filler materials, resulting in a gasket that can withstand thermal cycling, pressure fluctuations, and flange movements without loss of sealing integrity. We also tend to various client demands for valves and special sealing solutions by designing oval shaped spiral wound gaskets.

Design and Sealing Principle

Spiral Wound Gaskets are manufactured by spirally winding a pre-formed metal strip with a soft filler material, creating a resilient sealing element. Under bolt load, the gasket compresses to form a tight seal while the metal windings prevent over-compression and provide structural strength.

Depending on application requirements, Spiral Wound Gaskets can be supplied in the following configurations:

Without Inner and Outer Rings

With Inner Ring

With Outer Ring

With both Inner and Outer Rings

The inner ring prevents inward buckling and protects the gasket from process media, while the outer ring acts as a compression stop and ensures proper centering within the flange.

Materials of Construction

Metal Windings

- Stainless Steel (304, 316, 316L, 321)

- Alloy Steel

- Duplex / Super Duplex Stainless Steel

- Nickel Alloys such as Hastelloy and Monel

Filler Materials

- Flexible Graphite

- Non Asbestos

- PTFE

- Mica (for high-temperature applications)

Material combinations are selected based on operating pressure, temperature, chemical compatibility or entirely based on client’s specifications as well.

Standards and Pressure Ratings

Spiral Wound Gaskets are manufactured in accordance with ASME B16.20, with dimensions suitable for ASME B16.5 and ASME B16.47 flanges. They are available for pressure classes ranging from ASME Class 150 up to Class 2500, depending on gasket design and service conditions.

Why Choose Our Spiral Wound Gaskets

Our Spiral Wound Gaskets are manufactured with strict dimensional control and consistent winding density to ensure repeatable sealing performance. With a strong understanding of flange design, bolt loading, and service conditions, we supply gaskets that meet both standard and application-specific sealing requirements.

Applications

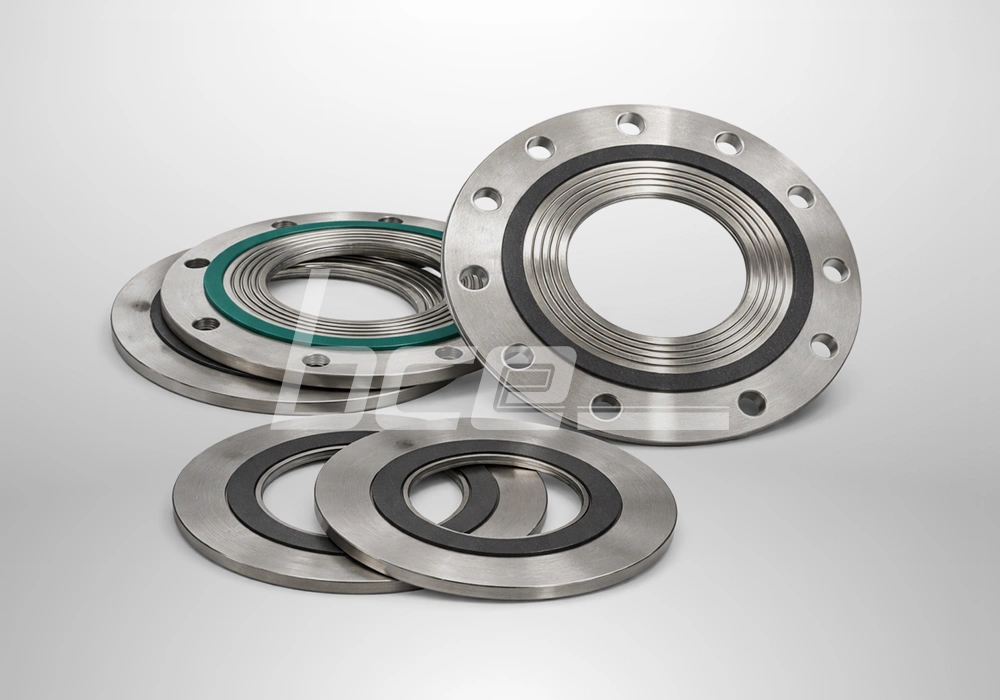

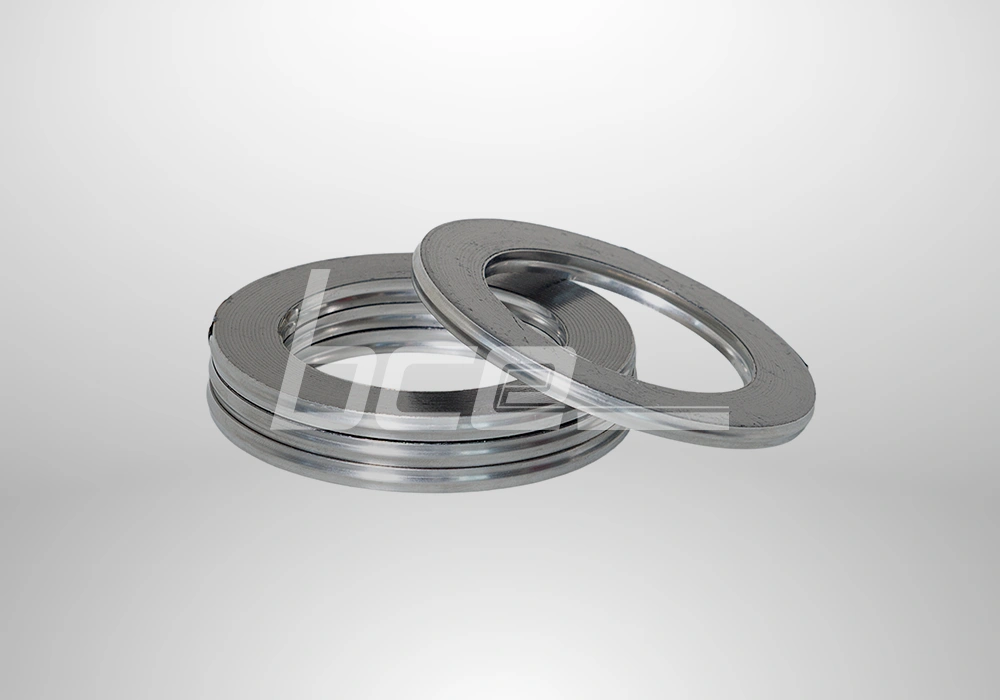

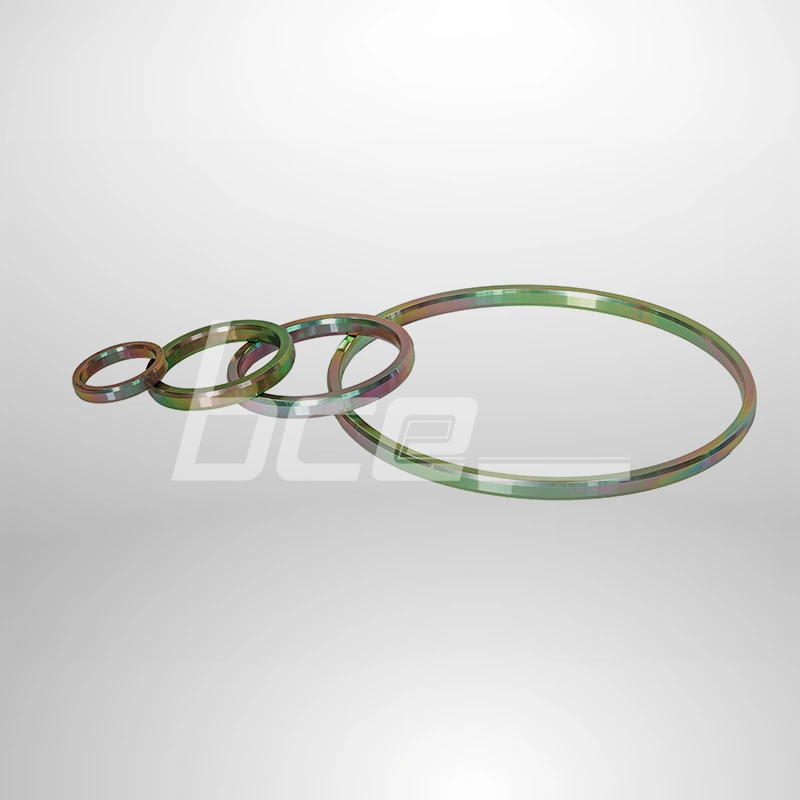

Ring Type Joint (RTJ) Gaskets

Ring Type Joint (RTJ) Gaskets are precision-engineered metallic gaskets designed for very high-pressure and high-temperature applications. They are primarily used with RTJ flanges where metal-to-metal sealing is required to achieve maximum joint integrity.

Ring Type Joint (RTJ) Gaskets are precision-engineered metallic gaskets designed for very high-pressure and high-temperature applications. They are primarily used with RTJ flanges where metal-to-metal sealing is required to achieve maximum joint integrity.

Design and Sealing Principle

RTJ gaskets seal by plastic deformation of the gasket material into the flange groove under bolt load, creating a tight metal-to-metal seal. This sealing method makes RTJ gaskets highly reliable for severe operating conditions.

They are typically supplied in:

The gasket profile is selected based on flange groove design and applicable standards.

Oval Type

Octagonal Type

Materials of Construction

RTJ gaskets are manufactured from solid metal, including:

- Soft Iron

- Stainless Steel (304, 316, 316L, 321)

- Alloy Steel

- Duplex / Super Duplex Stainless Steel

- Nickel Alloys such as Hastelloy and Monel

Material hardness is carefully controlled to ensure proper sealing without damaging the flange grooves.

Standards and Pressure Ratings

RTJ gaskets are manufactured as per ASME B16.20 and API 6A, suitable for ASME Class 150 up to Class 2500flanges, depending on design and application.

Applications

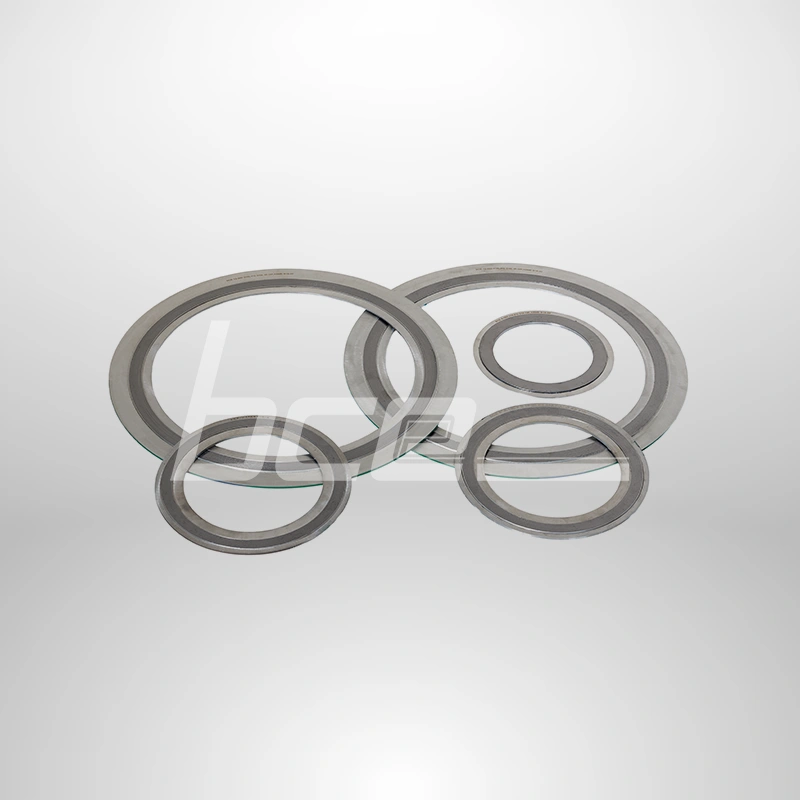

Kammprofile Gaskets

Kammprofile Gaskets are high-performance sealing solutions combining the strength of a metal core with the sealing efficiency of soft facing materials. They are widely used in applications where excellent sealing performance, reusability, and controlled compression are required.

These gaskets offer superior sealing compared to conventional soft gaskets, especially under fluctuating pressure and temperature conditions.

Design and Sealing Principle

Kammprofile gaskets consist of a serrated metal core with soft facing layers bonded on both sides. The serrations concentrate sealing stress, while the facing material enhances leak-tightness at low bolt loads.

This design makes Kammprofile gaskets suitable for both standard and demanding services.

Materials of Construction

Metal Core

- Stainless Steel (304, 316, 316L, 321)

- Alloy Steel

- Duplex / Super Duplex Stainless Steel

- Nickel Alloys such as Hastelloy and Monel

Facing Materials

- Facing Materials

- PTFE

- Other soft facing materials as per application

Standards and Pressure Ratings

Kammprofile gaskets are manufactured in accordance with ASME B16.20 and applicable customer specifications, suitable for ASME Class 150 up to Class 2500 flanges.