Simplex Basket Filters

Simplex Basket Filter

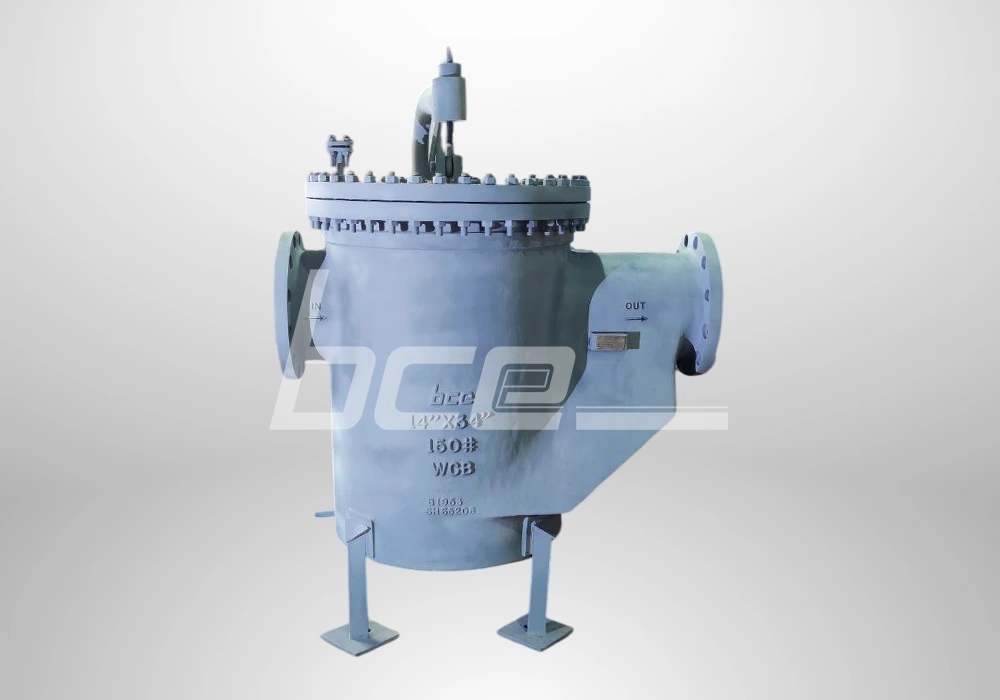

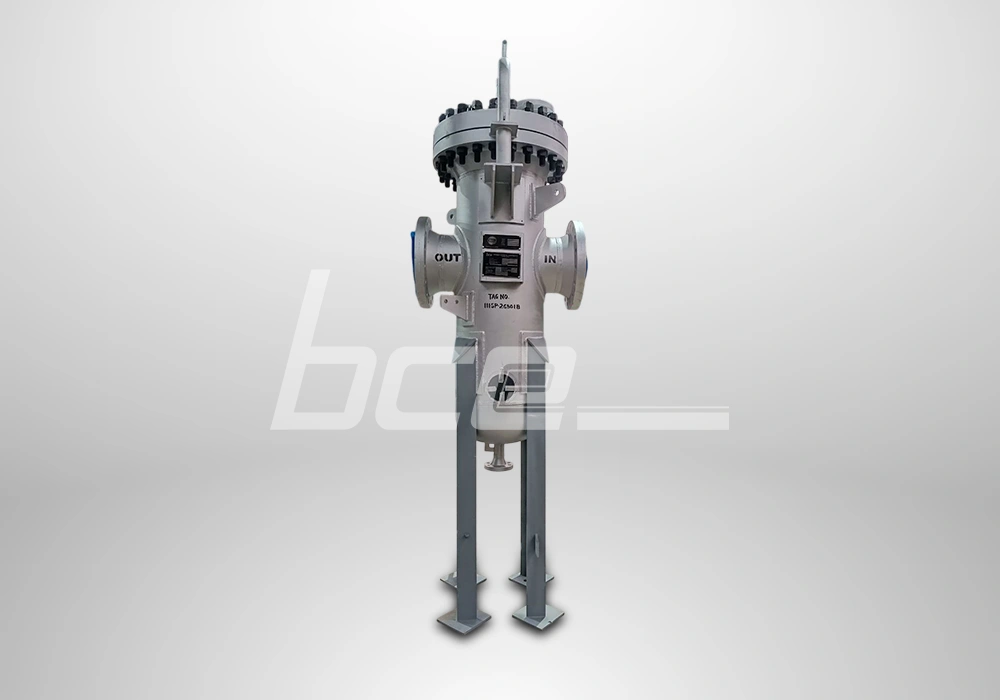

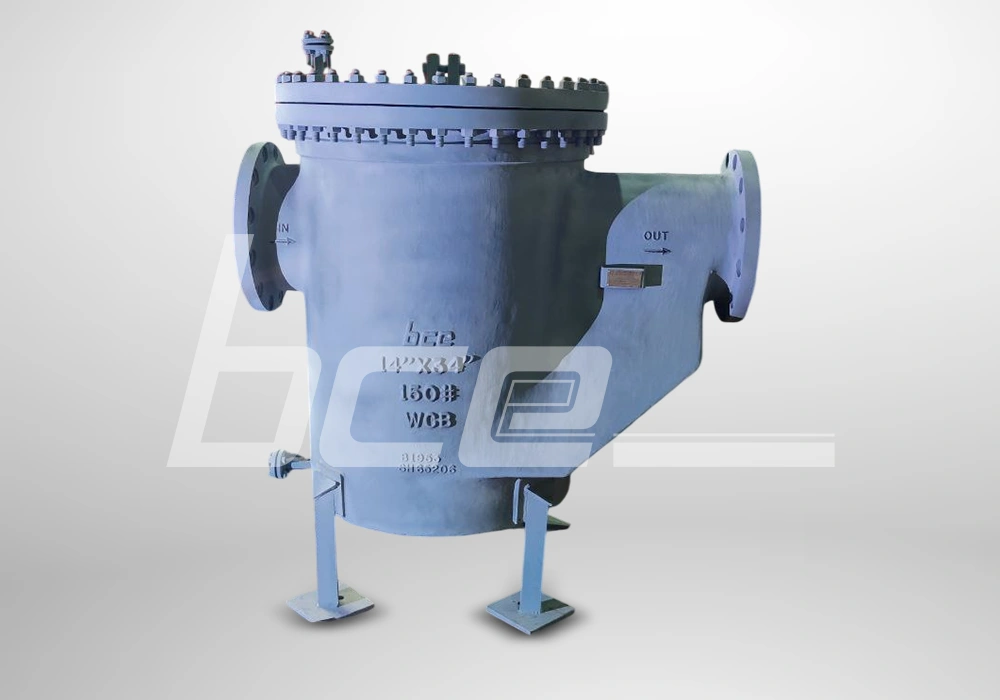

Our Simplex Basket Filters are designed to provide effective removal of solid contaminants such as scale, rust, weld slag, and debris from fluid systems, ensuring reliable protection of downstream equipment. Commonly referred to as Basket Strainers, these filters are widely used in applications where continuous filtration is required and brief shutdowns for cleaning are acceptable.

Simplex basket filters are particularly suited for systems handling moderate to high flow rates where ease of maintenance, robust construction, and efficient filtration are critical. Their large basket area allows for effective particle retention while maintaining a relatively low pressure drop, making them ideal for a wide range of industrial process applications.

Design and Construction

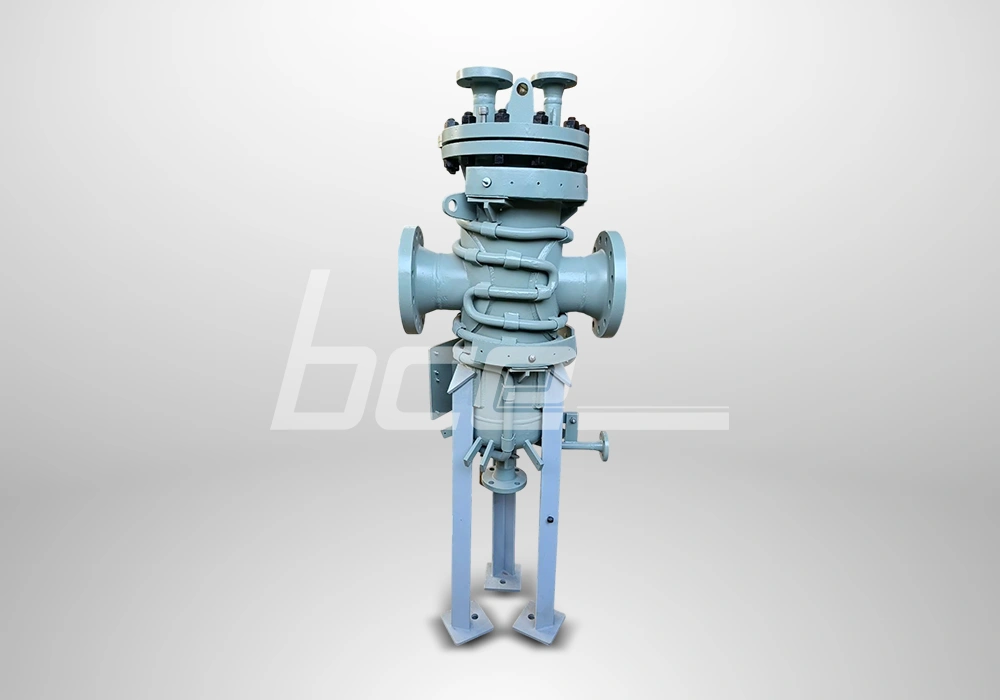

The Simplex Basket Filter features a vertically oriented cylindrical basket housed within a pressure-retaining body, allowing fluid to pass through the basket while trapping contaminants inside. This configuration provides a significantly larger filtration area compared to Y Type strainers, resulting in improved dirt-holding capacity and longer operating cycles between cleanings.

The basket element is easily accessible through a bolted top cover, enabling quick inspection, cleaning, or replacement. Simplex basket strainers are designed for durability and long service life, with reinforced baskets and rigid body construction to withstand differential pressure and operating stresses. The straightforward design ensures reliable performance in demanding industrial environments while keeping maintenance procedures simple and efficient.

In addition to standard designs, we also manufacture fabricated jacketed strainer variants for applications requiring thermal insulation, heating, or cooling of the process fluid. Fabricated variants of these strainers can also be supplied with PTFE, Rubber, or Glass Flakes Epoxy (GFE) lining for enhanced corrosion resistance in aggressive process fluids.

Our Products Highlights

Available Specifications

End Connections

- Flanged (RF / FF / RTJ)

- Butt Weld (Bevel End)

- Custom end connections on request

Pressure Ratings

- ANSI Class 150 / 300 / 600 / 900 / 1500 / 2500

- PN 10 / 16 / 25 / 40

- Custom pressure ratings available on request

Size Range

- 2” NB to 36” NB

- Larger sizes available on request

Basket / Screen Options

- Perforated baskets

- Wire mesh baskets

- Perforated plate with wire mesh lining

- Reinforced baskets for higher differential pressure

- Custom micron ratings as per service requirement

Materials of Construction

- Carbon Steel (WCB, A516 Gr.60/70)

- Stainless Steel (SS 304, 304L, 316, 316L, 321)

- Alloy Steel

- Duplex / Super Duplex

- Hastelloy

- Monel

- Other exotic materials on request

Standards and Compliance

- Designed in accordance with ASME / ANSI standards

- Flanges as per ASME B16.5 / ASME B16.47

- Face-to-face dimensions as per applicable standards or customer requirements

- Manufacturing and testing as per approved inspection and quality plans