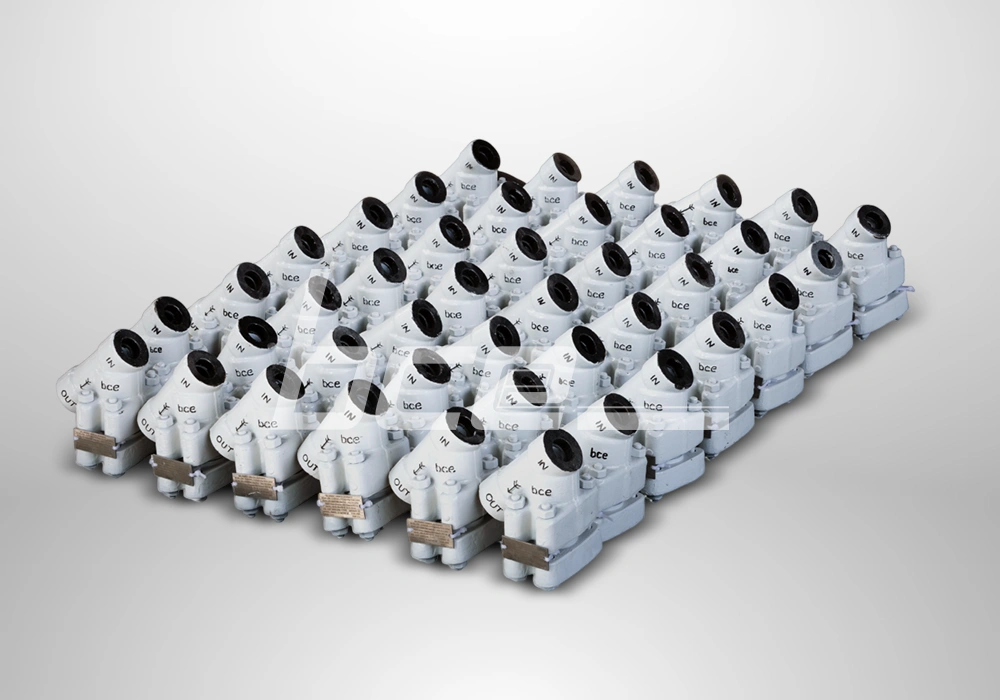

Y Type Strainers

Y Type Strainers

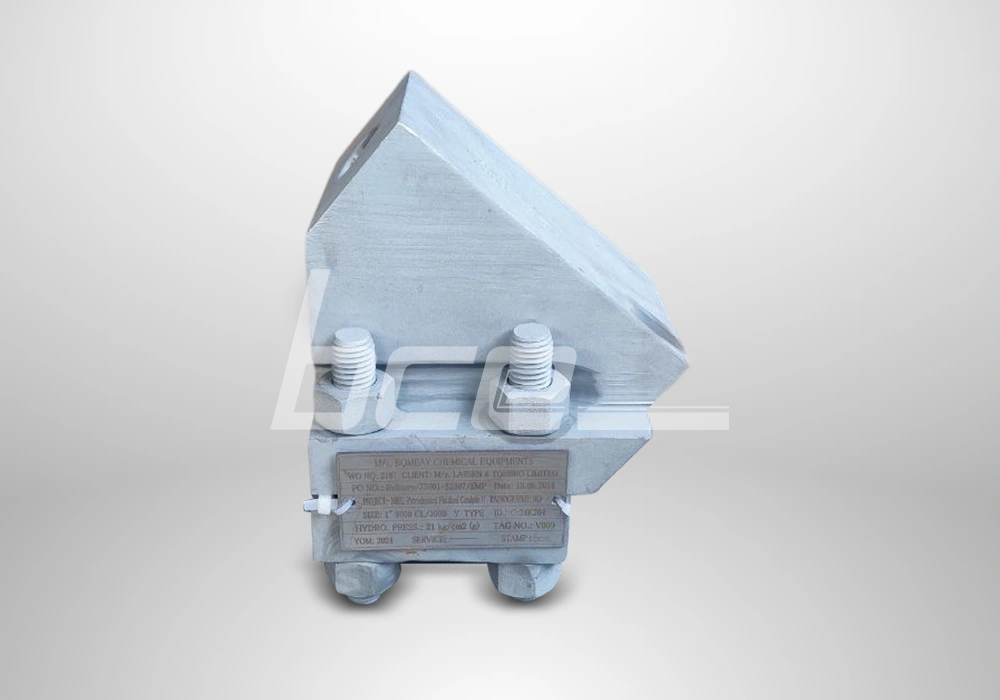

Our Y Type Pipeline Strainers are designed to remove unwanted solid contaminants such as scale, rust, weld slag, and debris from pipelines, ensuring reliable protection of downstream equipment including pumps, control valves, meters, and heat exchangers. Their compact angular design makes Y strainers particularly suitable for applications where space constraints exist while still maintaining effective filtration performance.

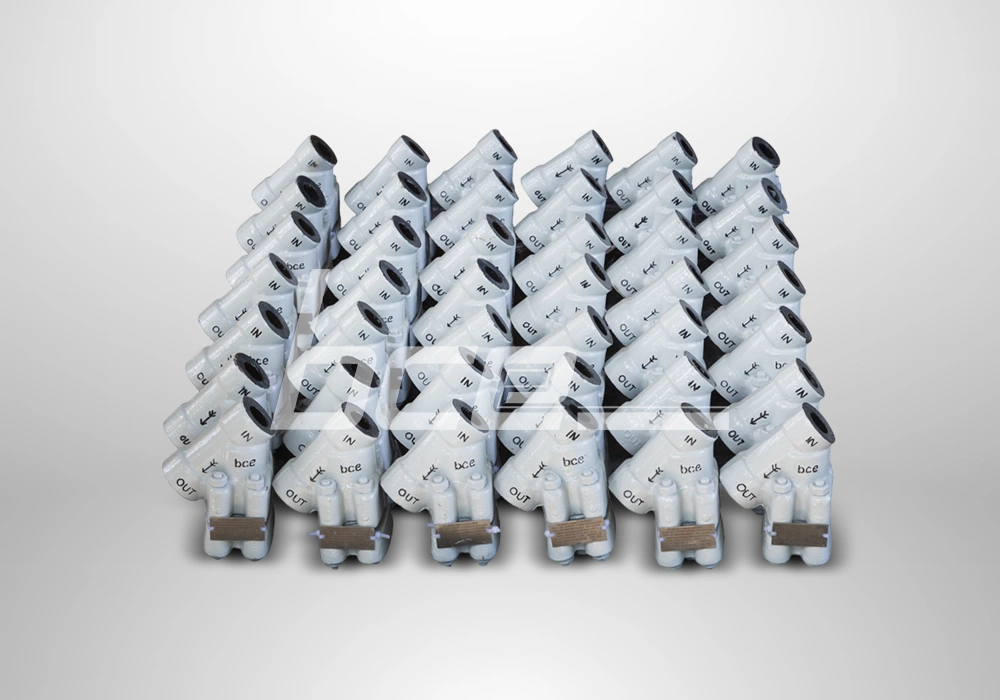

Widely used across process industries, Y Type strainers offer a practical balance between filtration efficiency and ease of maintenance. Their robust construction and adaptable design make them suitable for a wide range of pressures, temperatures, and service media, enabling consistent operation in both continuous and intermittent flow systems.

Design and Construction

The Y Type strainer features an angular body configuration that allows debris to collect in the strainer element without significantly restricting the flow path. This design ensures stable pressure drop characteristics while maintaining effective removal of suspended solids from the process fluid.

The strainer element available in perforated or wire mesh form is housed within a pressure-retaining body and can be easily removed for cleaning or replacement. Depending on size, pressure class, and service conditions, Y Type strainers are manufactured using casting, forging, or fabrication processes to achieve optimal mechanical strength, dimensional accuracy, and long-term reliability.

In addition to standard designs, we also manufacture fabricated jacketed strainer variants for applications requiring thermal insulation, heating, or cooling of the process fluid. Fabricated variants of these strainers can also be supplied with PTFE, Rubber, or Glass Flakes Epoxy (GFE) lining for enhanced corrosion resistance in aggressive process fluids.

Our Products Highlights

Available Specifications

End Connections

- Flanged (RF / FF / RTJ)

- Screwed / Threaded (NPT / BSP)

- Butt Weld (Bevel End)

- Socket Weld

Pressure Ratings

- ANSI Class 150 / 300 / 600 / 900 / 1500 / 2500

- PN 10 / 16 / 25 / 40

- Custom pressure ratings available on request

Size Range

- Forged Y Type Strainers: ½” NB to 1½” NB

- Cast Y Type Strainers: 2” NB to 24” NB

- Fabricated Y Type Strainers: All sizes available on request

Screen / Mesh Options

- Perforated plate screens

- Wire mesh screens

- Custom micron ratings as per service requirement

Materials of Construction

- Carbon Steel (WCB, A105)

- Stainless Steel (SS 304, 304L, 316, 316L, 321)

- Alloy Steel

- Duplex / Super Duplex

- Hastelloy

- Monel

- Other exotic materials on request

Standards and Compliance

- Designed in accordance with ASME / ANSI standards

- Flanges as per ASME B16.5 / ASME B16.47

- Face-to-face dimensions as per applicable standards or customer requirements

- Manufacturing and testing as per approved inspection and quality plans